PCTFE Coating (ULSHEED)

What is ULSHEED?

Original metal-free fluoropolymer coating with high chemical resistance and low dusting.

This offers a superior performance to general corrosion resistant fluoropolymer coatings (PFA etc.) in every aspects and has been used in a wide variety of situations.

Features

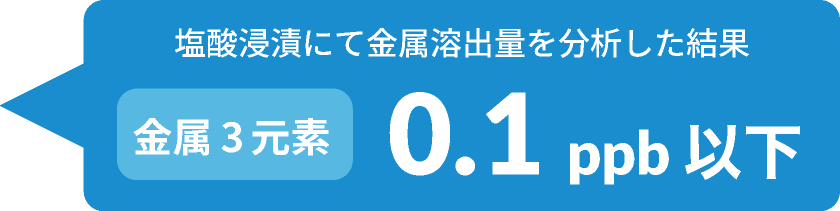

Low Metal Elusion

No metal used, leading to a better yield rate

* Dipping the sample in 3wt% HCL,

the immersion fluid measured by ICP-MS at 24th hour and 144th hour

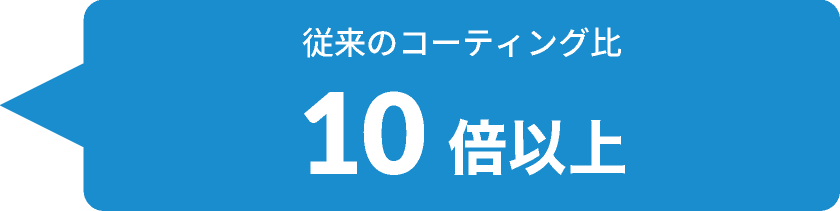

Excellent Durability

10 times more durable than incumbent coatings

* The values above are not guaranteed values

- Clean and durable recoatable coating whose main material is PCTFE, excellently non-permeable

- As shown in the graphs below, the characteristics of ULSHEED compared to conventional coatings

- ULSHEED for wafer-related components to improve your product qualities, yield rate & cost reduction

Metal Elusion

Metal elusion from ULSHEED is minimal

| Element | Dipping time duration | |

|---|---|---|

| 24h | 144h | |

| Al |

<0.1 | <0.1 |

| Fe | <0.1 | <0.1 |

| Mi | <0.1 | <0.1 |

* Test conditions

Dirt sticking to the coating surface of the test samples is evaluated after being washed with acid and ultrapure water.

- Dipping conditions

- HCl 3wt% at R.T.

- Test sample

- Quartz with ULSHEED

- Analysis method

- ICP-MS

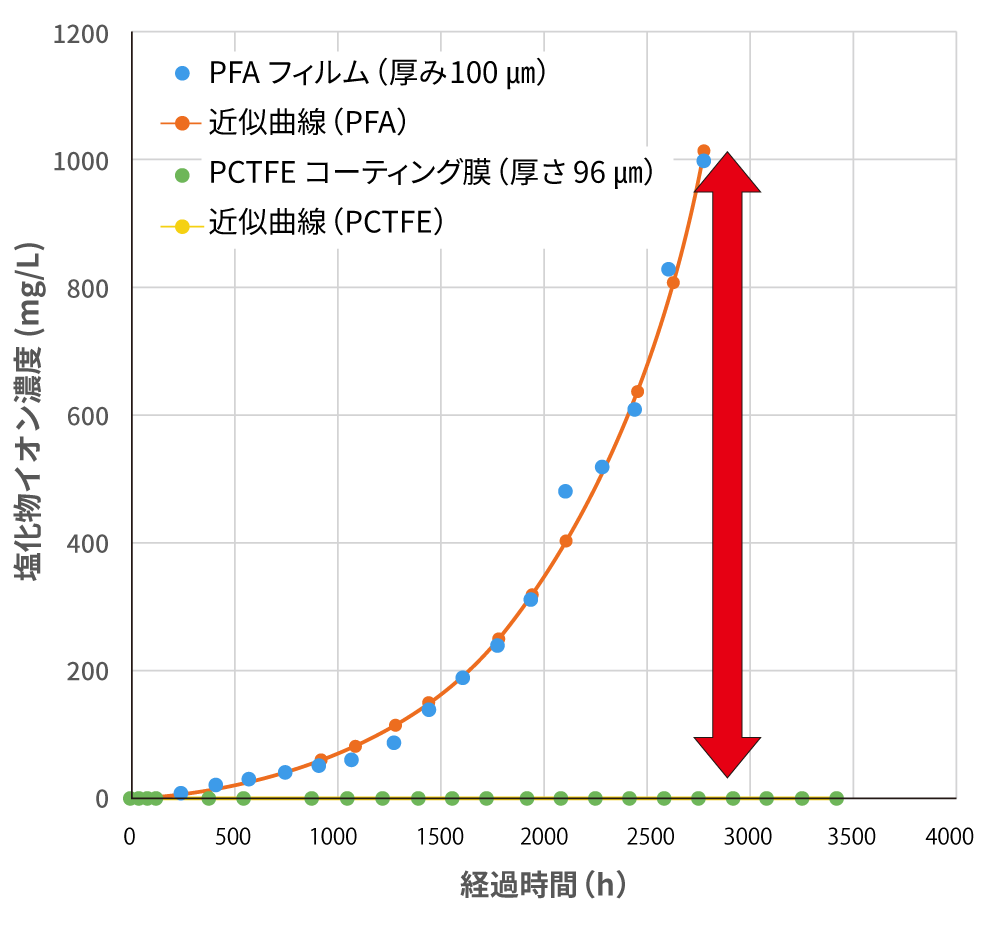

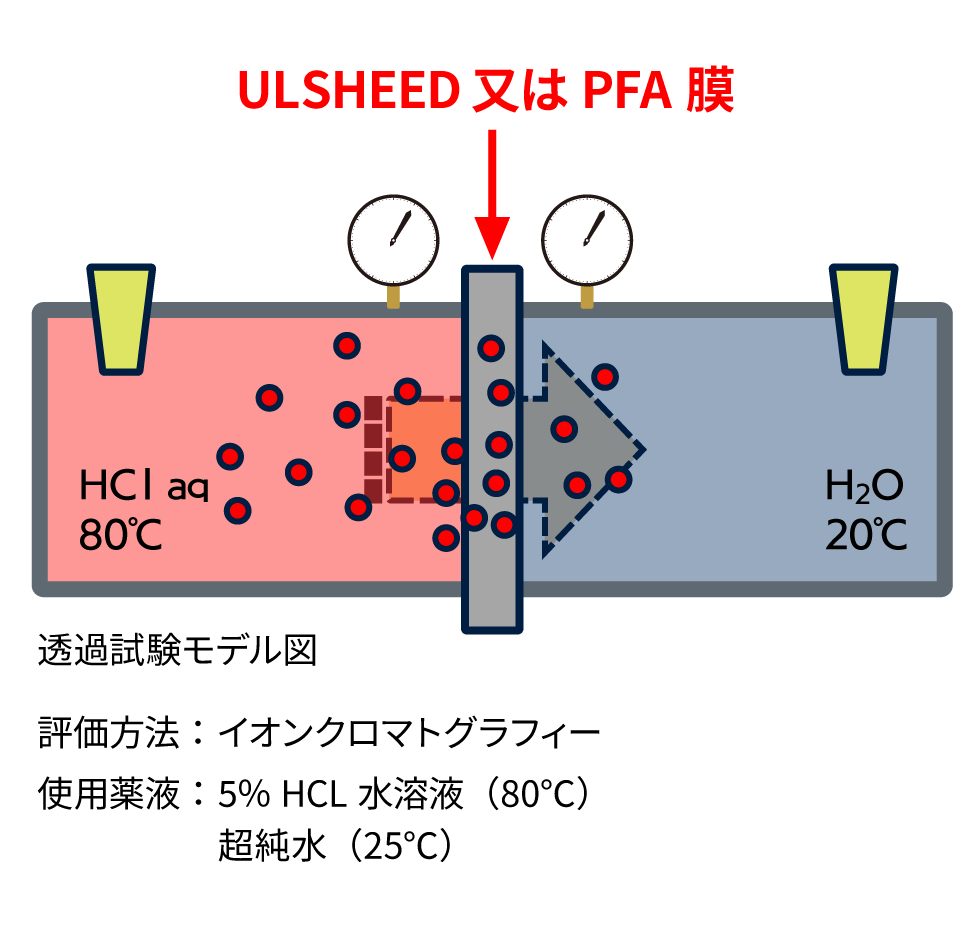

Permeability evaluation

ULSHEED’s permeability is significantly better than PFA

Ionic permeability test: ULSHEED and PFA coating film comparison

Cell set 1: One sell has ultra pure water while another has HCL(aq). Between the cells, ULSHEED coating film is set.

Cell set 2: One sell has ultra pure water while another has HCL(aq). Between the cells, PFA coating film is set.

As time passes, the HCL(aq) moves into the side where the ultra pure water is.

The ion concentration was measured by ion exchange chromatography (IEC).

In PCTFE, no chloride ion detected after 2780 hours

IN PFA, chloride ion detected after 236 hours and 1000mg/L of it detected after 2780 hours

Coating specification

Our PCTFE coating specification as follows.

Please contact us if you have requests not specified below.

ULSHEED Coating Process

ULSHEED is coated under controlled environment as cleanroom

ULSHEED Coating ProcessCase study: ULSHEED’s Durability

Proven to be over 10 times durable at a major semiconductor equipment manufacturer

Quartz components for 300mm wafer carriers of batch cleaning systems

- Conditions

- 49% HF at R.T.

- Process

- Dummy wafer reclaim

PFA coating ⇒ Pealed after 3 months

ULSHEED ⇒ No failure for 4 years

* The values above are not guaranteed values

- Substrate

- Quartz

- Film thickness

- More than 140μm